What are the characteristics of low-smoke and halogen-free power cables?

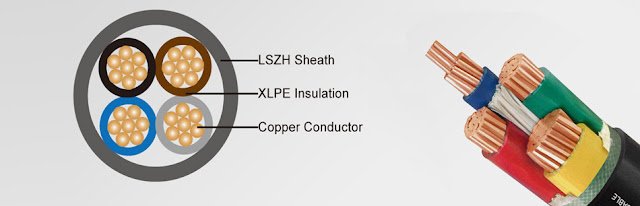

Low-smoke and zero-halogen power cables can also be called environmentally friendly cables, and low-smoke and halogen-free cables are mostly used in important occasions with high environmental requirements. Low-smoke halogen-free cables generally use red copper wire as the core. In the event of a fire, the wire sheath can continue to be energized to transmit data to avoid data loss, and when it burns, it does not drip and has no black smoke. 30% chance of escape. Low smoke zero halogen has the following five characteristics: 1. Zero halogen: The use of environmentally friendly insulating layer, sheath and special oxygen barrier materials not only have good electrical and physical and mechanical properties. It also ensures that the product does not contain halogen and solves the "secondary pollution" formed when it is burned. It avoids carcinogenic "dioxin" substances produced when traditional PVC wires are burnt. 2. High flame retardancy: The halogen-free low-sm...